Tailor-made WiFi networks for logistics warehouses and industry

Optimize your costs and increase productivity with our WAN, LAN and WiFi "as a Service" solutions

Tailor-made WiFi coverage for your warehouse or factory

High ceilings, large areas to cover, airtight materials, obstacles... warehouses and factories generally present very complex environments (in terms of WiFi wave propagation) requiring technological expertise coupled with extensive field experience.

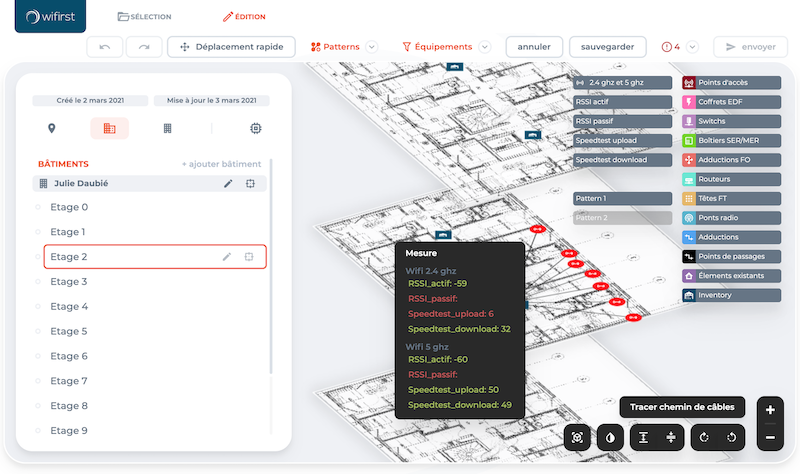

On-site radio coverage surveys are therefore an unavoidable step in studying the environment in real-life conditions, defining the layout of WiFi access points and designing the network's architectural base.

Wifirst, with its team of WiFi auditors, its in-house developed application and its unique methodology, offers the highest level of expertise on the market. Our teams draw on feedback from thousands of deployed and operated sites to develop best practices adapted to each technical constraint.

A WiFi network adapted to the new standards of logistics and connected industry

In recent years, industrial sites have undergone an intense digital transformation. Their activity has become inseparable from wireless connectivity, which represents an incredible vector of productivity for employees.

A reliable, high-performance WiFi network is essential for business terminals (handhelds, tablets, etc.) to communicate with software such as Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS). These tools are at the heart of today's industrial and logistics activities, enabling the management of orders, shipments, stock management and much more.

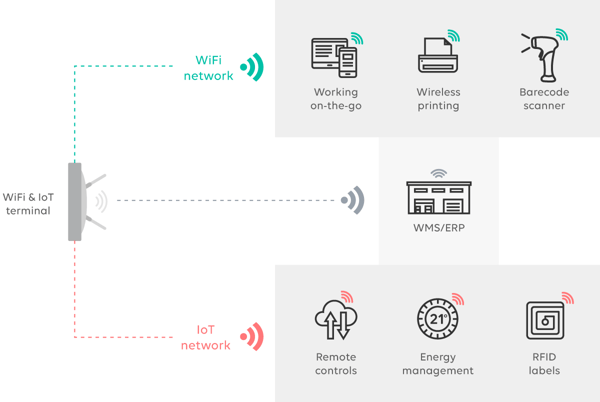

A converged infrastructure for WiFi and IoT applications

After the democratization of WiFi and Bluetooth in warehouses and factories for mobile working, it's now the turn of industrial IoT technologies to take off around several use cases:

- monitoring of various parameters (temperature, humidity, presence, etc.)

- process automation

- predictive maintenance

- resource and inventory management

Wifirst deploys converged wireless infrastructures that enable WiFi and IoT uses to be pooled around the same hardware, generating substantial savings in deployment and maintenance.

A critical need for network reliability and availability

Faced with the critical nature of WiFi in warehouses and industry, Wifirst relies on technical and human resources and industrialized maintenance processes to ensure the best quality of service on the market.

In order to establish a genuine relationship of trust, we make contractual commitments to our customers, notably with regard to :

- effective network coverage (100%)

- annual service availability (from 99.5%)

- guaranteed recovery time in the event of a blocking incident (from 4 working hours).

With Wifirst, you're assured of a network that works, and therefore optimum productivity for your industrial activity.

Our customers

Many players in the transport, logistics and industrial sectors use our WiFi as a Service solutions to cope with the criticality of the wireless network on their production sites.

📌 FAQ – Warehouse WiFi Solutions

1. Why is reliable WiFi critical in warehouses?

Short answer: Without stable WiFi, warehouse operations such as WMS, scanners, and IoT devices cannot function properly.

Details:

Modern warehouses rely on Warehouse Management Systems (WMS), barcode/RFID scanners, and automated vehicles. These systems demand low-latency, continuous connectivity. A single WiFi outage can stop order picking, delay shipments, and reduce overall productivity. Reliable WiFi ensures seamless operations and real-time data exchange.

2. What are the main challenges of deploying WiFi in warehouses?

Short answer: High ceilings, metal racks, and moving equipment make WiFi design complex.

Details:

- Physical barriers: tall racks, pallets, and machinery block signals.

- Interference: reflective metal surfaces and dense stock create dead zones.

- Roaming: workers and AGVs (automated guided vehicles) move continuously, requiring seamless handover between access points.

- Environmental factors: cold storage, dust, or humidity can affect performance.

3. Should warehouse devices connect to 2.4 GHz or 5 GHz WiFi?

Short answer: Use 5 GHz for performance and reliability; avoid 2.4 GHz when possible.

Details:

- 2.4 GHz suffers from interference, congestion, and fewer non-overlapping channels.

- 5 GHz provides higher bandwidth, more channels, and better stability.

- Modern scanners, tablets, and WMS devices should be configured to prioritize 5 GHz for critical tasks.

- With WiFi 6/6E/7, 6 GHz adds even more capacity for high-density environments.

4. How does poor WiFi impact WMS performance?

Short answer: Unstable WiFi causes delays, errors, and downtime in warehouse operations.

Details:

- WMS requires real-time communication between handheld devices and the central system.

- Packet loss or latency leads to scanning errors, duplicated tasks, or frozen screens.

- This translates into slower order fulfillment, inventory inaccuracies, and higher operational costs.

5. What are best practices for designing a warehouse WiFi network?

Short answer: Conduct a professional site survey, use directional antennas, and optimize for roaming.

Details:

- RF site survey: analyze coverage, interference, and capacity before installation.

- Access point placement: mount APs correctly (often under racks, not just on ceilings).

- Directional antennas: focus coverage down aisles to avoid signal overlap.

- Channel planning: separate APs to minimize interference.

- Roaming optimization: configure APs so devices switch seamlessly during movement.

6. How many access points are needed in a warehouse?

Short answer: It depends on warehouse size, layout, and device density.

Details:

- A small warehouse may only need a few APs, while a large facility can require dozens of strategically placed APs.

- Factors: ceiling height, racking layout, number of devices, bandwidth demand.

- Only a professional WiFi survey can determine the exact number and placement.

7. How can WiFi support IoT and automation in warehouses?

Short answer: WiFi is the backbone for IoT devices, sensors, AGVs, and robotics.

Details:

- IoT sensors (temperature, humidity, motion) rely on continuous connectivity.

- Automated Guided Vehicles (AGVs) and robots need stable roaming for navigation.

- Real-time analytics and predictive maintenance tools depend on low-latency WiFi.

- WiFi 6/7 enables high-density IoT connectivity with improved efficiency.

8. How do you ensure security in warehouse WiFi networks?

Short answer: By using enterprise-grade encryption, segmentation, and monitoring.

Details:

- WPA3 Enterprise for secure authentication.

- Network segmentation (guest vs operational vs IoT devices).

- Continuous monitoring for anomalies and unauthorized devices.

- Compliance with industry standards (e.g., GDPR, ISO).

9. What SLA (Service Level Agreement) should I expect for warehouse WiFi?

Short answer: A professional provider guarantees uptime, performance, and fast recovery.

Details:

- 99.9% availability commitments.

- Mean Time to Repair (MTTR) of a few hours.

- Proactive monitoring with 24/7 support.

- Performance metrics: throughput, latency, roaming efficiency.

10. How long does it take to deploy WiFi in a warehouse?

Short answer: From a few weeks to several months depending on complexity.

Details:

- Small facilities: 4–6 weeks.

- Large multi-site warehouses: 2–4 months.

- Factors: site survey, cabling, AP installation, testing, and fine-tuning.

11. What’s the difference between consumer WiFi and warehouse WiFi solutions?

Short answer: Consumer WiFi cannot handle the scale, density, and reliability required in warehouses.

Details:

Consumer gear = limited coverage, no roaming optimization, minimal security.

-

Warehouse WiFi = industrial-grade APs, directional antennas, SLA guarantees, centralized management.

-

Designed to support thousands of devices simultaneously with predictable performance.

12. How can I check if my warehouse is ready for WiFi deployment?

Short answer: Start with a professional site survey and needs assessment.

Details:

- Evaluate current connectivity issues.

- Map warehouse layout, racks, materials, and moving equipment.

- Assess device density (scanners, tablets, robots).

- Plan for scalability as operations grow.

👉 Contact Wifirst for a warehouse WiFi site survey and tailored design.

.svg.png?width=2560&height=412&name=Conforama_(depuis_2012).svg.png)