Your new Digital Workplace for the Fourth Industrial Revolution

What is Industry 4.0?

Industry 4.0, also known as the fourth industrial revolution, refers to the ongoing automation, digitisation, and connectivity of manufacturing processes and systems. This concept represents a significant shift from traditional industrial practices to a more connected and intelligent approach to manufacturing.

What are the key characteristics of Industry 4.0?

Interconnectivity

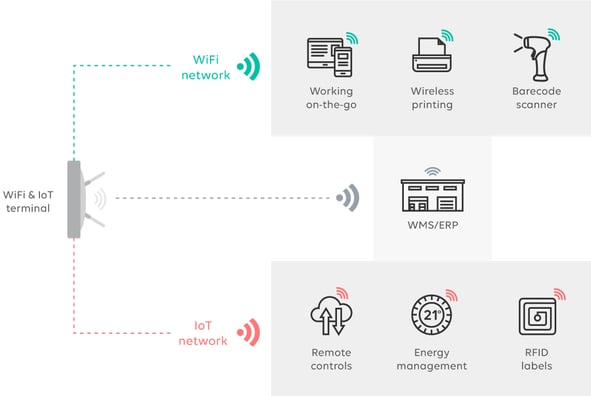

Industry 4.0 involves the integration of various components in the manufacturing process, creating a network where machines, devices, and systems communicate with each other. This interconnected ecosystem allows for real-time data exchange and collaboration.

Information Transparency

The use of digital technologies, sensors, and IoT (Internet of Things) devices provides a high level of transparency in the manufacturing process. Real-time data collection and analysis enable better decision-making and optimisation of production operations.

Technical Assistance

Industry 4.0 incorporates advanced technologies such as artificial intelligence, machine learning, and robotics to provide technical assistance in manufacturing. Machines can analyse data, identify patterns, and make decisions, leading to more efficient and autonomous production processes.

Smart Factories

The concept of a smart factory is central to Industry 4.0. Smart factories leverage digital technologies to create a highly flexible and adaptive production environment. Machines can communicate with each other, and production processes can be easily reconfigured to accommodate changing demands.

Customisation and Flexibility

With the capabilities of Industry 4.0, manufacturers can respond to individual customer needs more effectively. The production process becomes more flexible, allowing for customisation on a larger scale without sacrificing efficiency.

Sustainability

Industry 4.0 technologies can contribute to sustainability goals by optimising resource use, reducing waste, and improving energy efficiency. Smart monitoring and control systems help minimise environmental impact in manufacturing processes. Taking accountability of our carbon footprint is a priority for Wifirst.

Learn more about how we track our digital footprint here.

Learn more about how we track our digital footprint here.

What benefits does Industry 4.0 bring to your business?

Industry 4.0, is expected to have a profound and positive impact on businesses across various sectors. Let's look over a couple of ways this wave of technological advancements is destined to benefit businesses like yours:

Increased Efficiency and Productivity

- Automation and smart technologies lead to increased efficiency.

- Predictive maintenance and real-time monitoring minimise downtime, ensuring continuous staff operations.

- Optimisation of supply chain management through data-driven insights enhances overall productivity.

Cost Reduction

- Automation of repetitive tasks and predictive maintenance help reduce operational costs.

- Smart energy management systems contribute to energy efficiency and cost savings.

- Improved resource utilisation and waste reduction contribute to overall cost-effectiveness.

Enhanced Customisation, Personalisation and Quality

- Industry 4.0 enables mass customisation by allowing businesses to tailor products and services to individual customer needs.

- Smart buildings can quickly adapt to changing customer demands, providing a competitive edge in dynamic markets.

- Advanced monitoring and control systems ensure consistent product quality.

- Real-time data analytics enable quick identification and resolution of quality issues.

Flexibility = Innovation and New Business Models

- Decentralised decision-making and adaptive processes make businesses more agile.

- Flexible network integrations can easily be reconfigured to accommodate changes in product design or market demand.

- Industry 4.0 encourages innovation through the integration of emerging technologies like artificial intelligence, IoT, and augmented reality.

- Businesses can explore new revenue streams and business models, driven by data analytics and customer insights, both helpful for marketing and sales departments.

Improved Supply Chain Management for Retail and Warehouses

- Enhanced visibility and transparency in the supply chain through IoT and blockchain technologies.

- Predictive analytics optimise inventory management, reducing the risk of overstock or stockouts.

Empowering the Workforce

- Industry 4.0 technologies create opportunities for enhancing the workforces digital literacy and specialised skills.

- Collaborative robots (cobots) can work alongside humans, increasing productivity and safety.

Data Driven Decision-Making is Better

- Data analytics and machine learning provide actionable insights for informed decision-making.

- Real-time monitoring allows businesses to respond quickly to changing market conditions and customer preferences.

Sustainability and Environmental Impact

- Industry 4.0 technologies contribute to sustainable practices by optimising resource usage and reducing waste, both organic and electronic.

- Energy-efficient processes and eco-friendly manufacturing practices align with corporate social responsibility (CSR) goals.

Global Competitiveness

- Businesses that embrace Industry 4.0 can gain a competitive advantage in the global marketplace.

- The ability to adapt quickly to technological advancements positions companies as leaders in their industries.

What are some of the downfalls Industry 4.0 will bring to your business?

While Industry 4.0 holds significant promise for positive transformation in various sectors, there are potential challenges and negative impacts that businesses may need to consider. Here are some ways in which Industry 4.0 could have adverse effects on businesses:

Skill Gaps and Workforce Challenges

- Automation and the integration of AI may lead to the displacement of certain jobs, particularly those involving repetitive tasks.

- Workers in industries undergoing substantial technological changes may face challenges in adapting to new skill requirements.

- Businesses may face challenges in recruiting and retaining talent with the necessary digital skills.

- Change management may become crucial to overcome resistance and ensure a smooth transition.

Initial Implementation Costs and Economic Disparities

- The adoption of Industry 4.0 technologies often involves significant upfront costs for infrastructure, equipment, and training.

- Small and medium-sized enterprises (SMEs) may find it challenging to afford the initial investment required for a comprehensive digital transformation.

- Not all businesses may have equal access to the resources needed for adopting Industry 4.0 technologies.

- Economic disparities could widen, with larger enterprises gaining a competitive advantage over smaller counterparts.

.png?width=256&height=256&name=best-price%20(1).png)

Learn how Wifirst can help you make the initial investment at a lower cost here.

Cybersecurity Risks and Privacy Concerns

- The increased connectivity and reliance on digital technologies create new vulnerabilities to cyber threats.

- Businesses may face risks such as data breaches, intellectual property theft, and disruption of operations due to cyber-attacks.

- The collection and analysis of vast amounts of data in Industry 4.0 raise privacy concerns.

- Businesses must navigate regulatory frameworks and ensure responsible and ethical use of customer and employee data.

Never worry about your network security thanks to Wifirst’s Firewall as a Service

Dependency on Technology and Supply Chain Vulnerabilities

- Over-reliance on technology may leave businesses vulnerable to disruptions caused by technical failures, system crashes, or external attacks.

- Lack of contingency plans could lead to significant downtime and financial losses.

- Greater connectivity in supply chains may increase the risk of disruptions spreading across global networks.

- Businesses may face challenges in managing and mitigating the impact of unforeseen events on their supply chains.

Ethical Concerns

- The use of AI and automation raises ethical questions regarding accountability, bias in algorithms, and the potential for job loss.

- Addressing these ethical concerns is essential for maintaining trust among customers, employees, and stakeholders.

So is Industry 4.0 really revolutionary?

Overall, Industry 4.0 represents a transformative shift in how goods are produced, embracing the potential of digital technologies to create more efficient, flexible, and responsive manufacturing ecosystems. This paradigm shift has implications across various industries and is shaping the future of manufacturing worldwide.

The Fourth Industrial Revolution offers businesses the opportunity to transform their operations, improve efficiency, foster innovation, and stay competitive in an ever-evolving global market. Those that strategically leverage these technologies are likely to see positive impacts on their bottom line and overall business resilience.

However, while Industry 4.0 offers immense opportunities, businesses must proactively address the challenges associated with its implementation. Strategies for upskilling the workforce, ensuring cybersecurity, and fostering a culture of adaptability are essential to navigate the potential negative impacts and unlock the full benefits of the Fourth Industrial Revolution.

- Wifi (43)

- Hotel Industry (18)

- Digital Workplace (14)

- Behind the scenes (8)

- IPTV - Signage (8)

- Optical fibre (7)

- Green-IT (5)

- Retail (5)

- Education (3)

- Healthcare (2)

- Cybersecurity (1)

- General (1)

- Hospitality (1)

- PBSA (1)

- Student Accommodation (1)

- Telephony (1)

- Tips and tricks (1)

- Tourism (1)

- Wifirst (1)

You May Also Like

These Related Stories

The Power of WiFi and AI Integration

Managed WiFi vs In-house WiFi: Which Network Strategy is Right for Your Business?